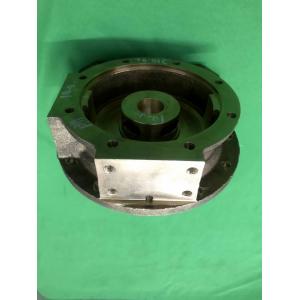

Customized High Precision Casting Precision Cast Parts Support Seat

Product Features of Precision Cast Parts Support Seat:

- High Precision: The support seat is manufactured using precision casting techniques, ensuring precise dimensions and shapes to ensure proper fit with other components.

- Strength and Durability: With appropriate material selection and casting techniques, the support seat offers high strength and durability, capable of withstanding heavy loads and long-term use.

- Complex Structures: The support seat can have complex internal structures and external shapes to meet the requirements of different applications.

- Corrosion Resistance: Depending on specific needs, the support seat can be made from corrosion-resistant materials to withstand harsh environmental conditions.

Applications of Precision Cast Parts Support Seat:

- Industrial Equipment Support: The support seat is commonly used in industrial equipment to support and secure various components, machinery, or devices. They provide a stable foundation, ensuring smooth operation and minimizing vibrations.

- Structural Support in Construction: In the construction industry, support seats are used to support and stabilize columns, beams, or other structural elements, ensuring the stability and safety of the structure.

- Aerospace Applications: Support seats play a vital role in the aerospace industry, supporting and securing various components of aircraft, rockets, satellites, and other spacecraft.

- Vehicles and Transportation: Support seats are widely used in the chassis, seats, suspension systems, and other parts of vehicles and transportation equipment, providing necessary support and stability.

In summary, Precision Cast Parts Support Seat offers high precision, strength, durability, and versatility, making it suitable for various industries and applications that require support and fixation.

Specifications

1. Small Order Accepted

2. ISO certified.

3. Quick Delivery